Safety & Training

At Schoenfelder Renovations, safety and training are at the top of our priority list. We do all we can to protect our employees and clients, meaning we follow all OSHA requirements for workplace safety. We also want our employees to be the best trained and most knowledgeable in the business so that you have an excellent facility for your business.

Training Procedures for Expert Workmanship

Sealants

We train our crews on the design, removal, and installation of sealants and control joints. We built a training wall in our shop for hands-on practice. After the course completion, each installer is tested to prove that he understands and can deliver properly shaped joints in the field. We then certify the installers to ensure that we have consistent quality in the field.

Tuck Pointing

Tuck pointing costs have risen dramatically in the past decade. We built a training and testing wall with CMU and clay brick in our shop. When we have a project that requires tuck pointing, we are able to test a crew to ensure that they are experienced at grinding out the failing mortar and installing the new mortar. This keeps costs down and ensures consistent quality for our clients.

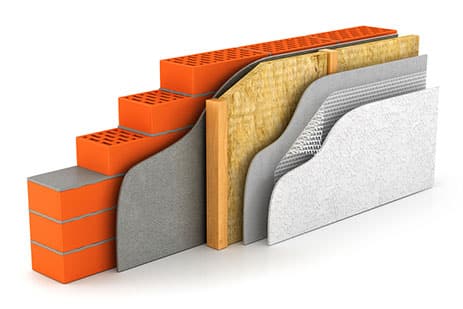

EIFS

Many of our clients need EIFS repairs (exterior insulated foam system) on their hotels, retail, multi-housing, and other commercial projects. It is extremely hard to find qualified subcontractors who are willing to do small repairs. Going rates for EIFS repairs are over $100/hr.

To remedy this situation for our clients, we brought in manufacturers and expert installers to teach our subcontractors the basics of EIFS repair and installation. We were able to let them practice patching holes and cracks and blending the texture on our training wall. This increased their abilities and allows us to provide these services to our clients in a cost-effective manner.

Safety Built into our Procedures

Boom/Forklift

We utilize booms, lulls and forklifts every day on our projects. Our sites have multiple crews and many people performing different tasks. It is important that everyone operating a piece of power equipment understands the safety requirements and is experienced in the operation of the equipment. People’s lives are at stake, and because of this, Schoenfelder Renovations partners with our power equipment providers to have some of our employees go through classes to become trainers.

They then teach and test subcontractors to safely use power equipment. We then go on site to test the individuals by observing their competence when operating the power equipment. If they can demonstrate the necessary skills and knowledge, our trainers are able to certify them in the safe use of the power access equipment. We work hard to make sure every person goes home safely at the end of the day.

Swing Stage

Schoenfelder Renovations is known for being able to complete high work requiring swing stages from 10 to 20 to 30 stories up in the air. This type of work can be intimidating, but in reality, these jobs result in far fewer accidents than cleaning gutters on a residential house. Schoenfelder partners with our equipment suppliers to train and certify our crews to work safely on swing stage equipment. This allows us to make sure everyone is safe on our projects and allows us to have more experienced swing stage operators—which ultimately keeps costs down for our clients.

Personal Safety Protection

Making sure that our crews are safe and following OSHA Standards in fall protection, eye protection, hearing protection, and respiratory protection is of the utmost importance to Schoenfelder Renovations. We have given out thousands of foam ear plugs, safety glasses, bright yellow safety shirts, as well as fall-protection harnesses, tethers, and life lines to our crews and others. The price for this safety gear is minimal, but sleeping better at night is priceless.

Safety Coordinator

Schoenfelder Renovations employs a full time safety coordinator who trains and tests crews. He also inspects sites to ensure that proper safety practices and record keeping are being followed. He provides the site supervisors with content and reminders for weekly safety meetings. When he encounters a crew member that is not following proper safety procedures, he will first remind them of the correct procedure and the importance of it. If he observes that incorrect practice again, he writes up a report to the office and the subcontractor, documenting the violation. At first the crews didn’t like his involvement. Over time, they have realized that we do this out of concern for their safety.

Schoenfelder Renovations takes the welfare of our employees and clients seriously. We serve the entire nation from coast to coast. We specialize in commercial renovation services including windows and doors, siding, flooring, roofing, painting, and restoration services. You’ll appreciate our fixed-price bidding process. Contact us at (952) 345-2900 to request a bid.